As with many other WS planes, it is not known how soon after the company started Plane production that they introduced the A78, but the first labels suggest that this plane may have been one produced at the beginning of plane manufacturing. And ‘introduce’ they did, since I cannot find any other manufacturer who produced a Double-armed Duplex Rebate plane before that of the A78. STANLEY never made one, the RECORD 778 was produced from 1959, and this plane was made after they had acquired WODEN Tools, who produced a W78. The W78 was itself a copy of the A78 […see later here for information on this transition] and was produced after WODEN Tools acquired the WS Plane manufacturing division in 1953.

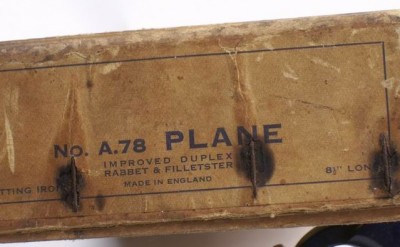

On the label it is named as an “Improved Duplex Rabbet and Filletster” Plane. In an advert circa 1950 this plane is called an A078, whereas shortly after (1951) it is shown as A78. As no A078 plane has surfaced and no other plane number is prefixed with a zero [except the spokeshave A051], I am inclined to think that A078 was a ‘typo’ error. See ‘History of WS Tools‘ section for the adverts alluded to here.

The base length of the A78 was always around 21.3cm long x 3.7-3.8cm wide and it weighs 3.3/4 lbs.

This photo is to show you how the 78 planes can be packed into the box and in fact it would be even better if the wooden handle was separated from the body so as to avoid the fence scratching the handle’s varnish. But this arrangement may not have been how they were issued from the manufacturer, we will never really know, however this packaging satisfies my past frustration at getting all the components into that small box!!

This photo is to show you how the 78 planes can be packed into the box and in fact it would be even better if the wooden handle was separated from the body so as to avoid the fence scratching the handle’s varnish. But this arrangement may not have been how they were issued from the manufacturer, we will never really know, however this packaging satisfies my past frustration at getting all the components into that small box!!

BLADE:

All of my A78 planes show a B3 blade, however I do possess an orphaned B3a blade which would therefore indicate that the A78 was produced in the middle to late WS plane manufacturing history. The blade is 10.3cm long and 38.5mm [1.1/2″] wide.

LEVER CAP and SCREW:

Cast from solid brass, polished and lacquered or varnished. There are 2 Types of Lever Cap: Type 1 planes may be fitted with either Type cap, but Type 2 planes always had a Type 2 Lever cap. (Read further for descriptions of the plane Types)

Looking at the upper face of the cap… Type 1 shows a concave sweep of the ridge down to the leading edge whereas Type 2 shows a convex sweep. The Type 1 cap has a screw with fine vertical knurling whereas Type 2 caps have coarse vertical knurling….as visible below. For details of the screw holding the Lever Cap to the body… see below under FRONT HANDLE. The Lever Cap screw is 2.3cm long with the thread being 4mm wide.

Type 1 Type 2

Type 1 is slightly longer at 80mm than Type 2 at 78mm, both being 36mm wide.

FENCE and SCREWS:

The fence is 21cm long and the coarse vertically knurled nickel plated iron screws are 17mm long and 4mm thick.

2 Types Type2 Type1

As shown above you will note that there were 2 types of Fence which belonged respectively to the 2 Types of A78 that I have found. Type 2 fences show a more straight angular appearance at the attachment arm whereas Type 1 fences show a rounded shape here and a small rise up to the screw position. Type 2 fences all have casting numbers on the top or inside of the fence whereas Type 1 fences do not have casting numbers.

FENCE ARMS:

The 2 arms [officially called supporting rails] are around 8.5cm long and are 6mm thick having cut threads which are screwed into the body. This screw action is aided by having a hole drilled through the arm at the distant end in which to insert a small bar. (Something that is missing in the design of many arms of planes from other manufacturers). They are made of steel, but the nickel plating is usually worn thin from usage. ( WODEN arms (W78) are much thicker at 8mm. and the threads will not fit the A78).

ADJUSTABLE DEPTH GAUGE and SCREW:

The bearing surface of the gauge is 6.4cm long and 1cm wide at the area where there can be no blade contact at the side. Note that the trailing arm is longer than the leading arm whereas other manufacturers had equal length arms. The majority of gauges seem to show casting numbers at the top inside or outside face, and the gauges that fit the Type 1 planes have a wider extruded groove to fit in the wider slot of Type 1 planes…..see below left hand gauge in each photo. The gauge screw is 2.8cm long with a thread diameter of 4mm. and should always have an accompanying washer. The nickel plated screw has coarse vertical knurling (see below), although one of my later planes shows fine vertical knurling.

Type 1 Type 2

Type 1 Type 2

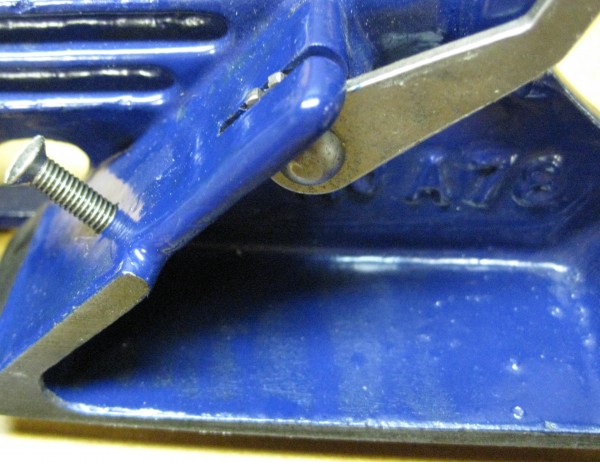

BODY:

The body shows the major differences between Type 1 and Type 2 planes. On both types the base is around 21.3cm long and 38.5mm wide.

When the cutter is in the central position fine vertical adjustment of the cutting iron is controlled by a plated steel lever.

But the ‘No A78‘ cast inside the body just forward of the handles differs as shown below:

Type 1

Type 2

The ‘nose’ casting also differs:

Type 1 Type 2

The left hand side ‘flats’ [measured from the back of the front mouth up to the curve where the paint intercepts] varies (see photos above here). Type 1 is 48mm and Type 2 is 54mm long.

Also the ‘nameplate’ differs, but this can be hard to see:

Type 1 Type 2

The stippling on the handle of Type 1 has but a little distinct border, whereas Type 2 does, this though is not a distinctive feature to go by, and may be hard to see:

Type 1 Type 2

FRONT HANDLE:

Always made from Beech and having a clear yellow tinged varnish, it measures 85-90mm from the top to the pointed bottom, with a max. diameter of 33-36mm and a ‘neck’ of 16-18mm. The shape may vary slightly due to ‘batch’ variation, but I have only 1 example of a real variation as shown in the photo below…that being the handle on the right. The handle on the left is the more usual shape. It should be noted that there is a circular pressed steel washer at the bottom of the screw hole in the top of the handle to alleviate the forces exerted on the wood by the screw head. The screw is a 2cm long , 4mm thread diameter oval slot headed steel screw exactly the same as that holding the Lever Cap. Each plane was supplied with 2 of these screws, one to hold the front handle and one to help secure the blade.

I believe that WS , WODEN and RAPIER were the only companies to supply this forward handle for the 78. [Worth noting here is that RAPIER also had a similar shape to WS for their Bench plane lever caps]

The WODEN handle (below) was thicker, less graceful and covered in dark brown varnish.

SPUR and SCREW:

Distinctively different again to all other manufacturers’ 3 point spur, the WS (and also WODEN) spur is a ‘circular hardened steel disc incising cutter’ , edge flattened in the ‘storage’ position. It has a diameter of 13.5mm, 2mm thick with a 5mm central hole.

The small steel slot countersunk screw is 9.5mm long with a 4mm thread diameter.

This design gives therefore a multitude of cutting edges for use in cross-grain work.

This design gives therefore a multitude of cutting edges for use in cross-grain work.

REAR HANDLE TRANSFER:

The only transfer that I have seen is RHT2 and placed on top of the rear metal handle and readable from the toe of the plane. Very late planes may not have a transfer.

RHT2

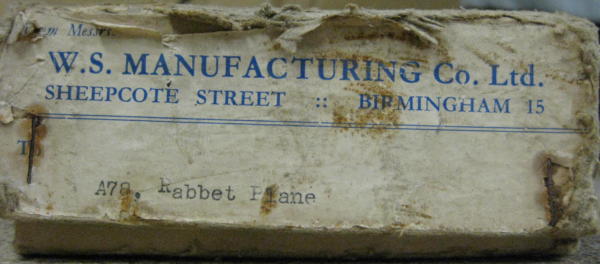

BOX and LABEL:

The box lid is 26.2cm long x 12.5cm wide x 4.5cm deep. The cardboard is about 1.5mm thick, but a later box of orange coloured cardboard is only 1mm thick.

The label below shows a Type 1 plane with a crude artist’s impression of the front wooden handle.

The very earliest label I can find is typed on an Address label and simply labelled as a ‘Rabbet Plane’ [To: From:] [Photo below right] From then we progress to these labels [below]which were the very first labels [plain] produced by WS before the later coloured and illustrated label [above] was available. I can now confirm that this may be true since discovering this label on other boxed planes in the UK. BUT, I have the Full colour label [above] showing 25/- on each of 2 boxes and the ‘Plain‘ label as both 22/- and 27/6. Could the latter have been a re-priced object on one that had been in stock and not sold in so many years!!??

Type2A :

Recently, through reports from Australia and Scotland it has come to light that there is a variation of Type 2 A78 planes. It has been noticed that the outer half of the rear blade support [split in 2 by the depth adjusting lever] has been removed. Evidence suggests that this was done prior to painting the base. The surface left is not a smooth cast surface, more of a hacksaw job! It is suggested that this metal removal may have speeded up the hand insertion process of the rivet holding the Lateral Lever. With the Type 2, damage could have been inflicted on the painted base by a misguided blow with the hammer in the insertion of the rivet, and since the Ladies on the line were on piecework they would have been in a hurry. Too many damaged planes may have prompted this small modification.

THE TRANSITIONAL PLANE A78–W78:

When Woden Tools purchased the WS Tool Company in 1952 they purchased the stock on hand and the rights to all patent planes that endured with WS.

The major purchase must surely have included the right to manufacture a double arm rebate plane similar to the the WS A78. I am unable to locate a patent for this design, but I feel sure that it was purchased by WODEN Tools, along with the WS company holdings. They would also have received the wooden patterns for Type 1&2 A78. Obviously they chose to carry on producing what they considered to be the better casting, [Type 1] and they did the same modification to the rear blade support as in Type 2A above, but since the plane was cast with the modification, it is much ‘cleaner’.

After many years I have managed to secure a fine example of the very first W78 that was produced by WODEN Tools and it certainly is a Hybrid.

They modified the diameter of the ‘arms’ and their respective tapped holes in the body to be larger at 8mm. They used the Type 2 casting of the WS fence and drilled out the hole in the top of the rear handle to a larger size. [ I do not know why!]

On the left is the original WS casting and on the right is the modified WODEN casting that reveals the depth adjuster completely.

Obviously they had to erase the WS name and logo from the side and inside of the wooden plane pattern and instead initially applied water transfer logos.

Here you will note that the base casting conforms to that of an A78 Type 1 (see the indent casting at the top of the nose)

When WODEN eventually got into the real production of W78, the castings show a similar casting to that of the A78, but the nose area is a lot more solid and less fragile.

Below are photographs of a later complete WODEN W78 plane:

It must therefore be stated that the modified A78-W78 seen here represents the dying embers of a great company, but also the continuation of a wonderful original idea.